Projects

Tata Chemicals, Northwich (2020-22)

All steam, condensate, turbo gas, liquor, effluent and river water pipework was fabricated off-site, installed onto steel frame modules and transported to site. On site installation of carbon steel, stainless steel, galvanised Victaulic piping, butt fusion plastic and final connection spools between bridge sections.

All our materials and welding processes are fully traceable with certification and document logs, all to ASME B31.3 standards. Ultrasonic and X-ray NDT carried out at our fabrication facility and on site.

Alderley Park, AstraZeneca, Alderley (2021)

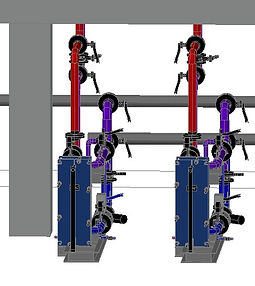

HTHW to LTHW conversion in a challenging environment that required high levels of security and safety. New 200mm LTHW distribution mains installed throughout the service voids to 13 plantrooms. Installation of 34 new LTHW to LTHW skid-mounted, plate heat exchanger (PHE) packages, all fabricated and assembled in our Leeds facility. Provided effective solutions for the phased swap overs from HTHW to LTHW across the site.

Sterling Pharma - New Energy Centre, North East (2020)

New-build installation of 1 x 3MW CHP Gas Engine with external dump rad, 2 x 12 bar rated WHB Boilers, 1 x 12 bar rated Fired Boiler and all associated boiler plant. Installation of pipework services including steam, condensate, feed water, natural gas, lubrication oil, HT water, LT water, RO water and water softening plant. The thermal insulation and metal cladding was then completed by our own Insulation Engineers. The pipework, galvanised steel supports, boiler flues, exhaust ducting and boiler access walkway system was all designed, fabricated and installed by us. All services extended from the new energy centre to the existing interface points.

Good Hope Hospital De-Steam Project, Birmingham (2022-24)

Installation of a new 200mm LTHW ring main around the entire site; many hours of survey work and planning went into integrating the new services in a working hospital with aged infrastructure. 18 plantrooms were fitted with our prefabricated LTHW PHE skids, serving existing secondary LTHW and DHWS systems. The energy centre refurbishment included the installation of three new LTHW boilers, all associated pipework, pipework support steelwork and boiler flue systems. External and roof-mounted plant was installed including heat pumps, buffer vessels and the replacement of 30 AHU coils and frost coils. All this whilst maintaining heating and hot water capability to the hospital.

Hospital services riser tower, Midlands (2023)

Fabrication of modular riser tower to client outline design, incorporating grade 316L stainless steel and HDPE pipework, fully tested, insulated and cladded in our Leeds facility. Built in four sections the tower was able to be transported easily and erected on site in three working days.

Heat Recovery project - Food Industry site, Cambridgeshire (2024)

Prefabricated PHE/pump skid, 30,000 litre buffer vessel, pipework and pipework supports delivered to site and assembled by our installation team. Utilising an existing LTHW circuit from the CHP plant, we installed new stainless steel pipework to various user interfaces on site.

BYK Additives - New Energy Centre, Widnes (2024)

Design, fabrication and installation of a new 19 bar steam boiler plant within an existing building, to the stringent safety standards expected on a chemical site. Carbon steel and stainless steel pipework to ASME B31.3 specifications. NDT carried out on all services. Stress analysis was implemented during the design of the pipework and support systems. The boiler flues along with the CHP exhaust ducting was also prefabricated, installed and insulated by us.

Birmingham Women’s Hospital Energy Centre, (2025)

A new build water source heat pump Energy Centre over three levels serving a large hospital. Galvanised steel skid packages, along with all associated pipework support systems, designed and fabricated at our Leeds premises. The pipework for this entire project was fabricated off site, eliminating the need for site welding and allowing us to fully document our QA to a high standard. Our large facility allows us to position equipment and trial fit pipework before it goes to site.

Hartlepool Hospital De-Steam project, Hartlepool (2024-25)

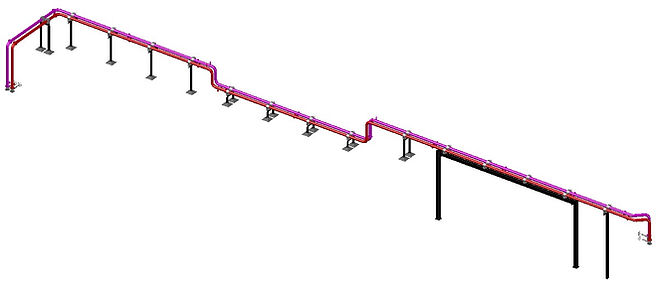

Design and installation of a new prefabricated LTHW ring main around the entire site; another project that required extensive survey work. 13 plantrooms were fitted with our prefabricated LTHW PHE skids, serving existing secondary LTHW and DHWS systems. The energy centre refurbishment included the installation of two new LTHW boilers, water source heat pipework support steelwork and boiler flue systems. The boiler house services were built on to skid packages, pressure tested and insulated in our Leeds facility. This enables us to cut down installation time on site and keep up to our high levels of QA. External plant was installed including heat pumps and buffer vessels along with the replacement of several AHU coils and frost coils. All buried water source plastic piping and pre insulated carbon steel pipework installed by our highly skilled site teams.